The Sustainability Report serves as summary about our principles, activities and efforts of a sustainable acting for the achievement of our strategic goals

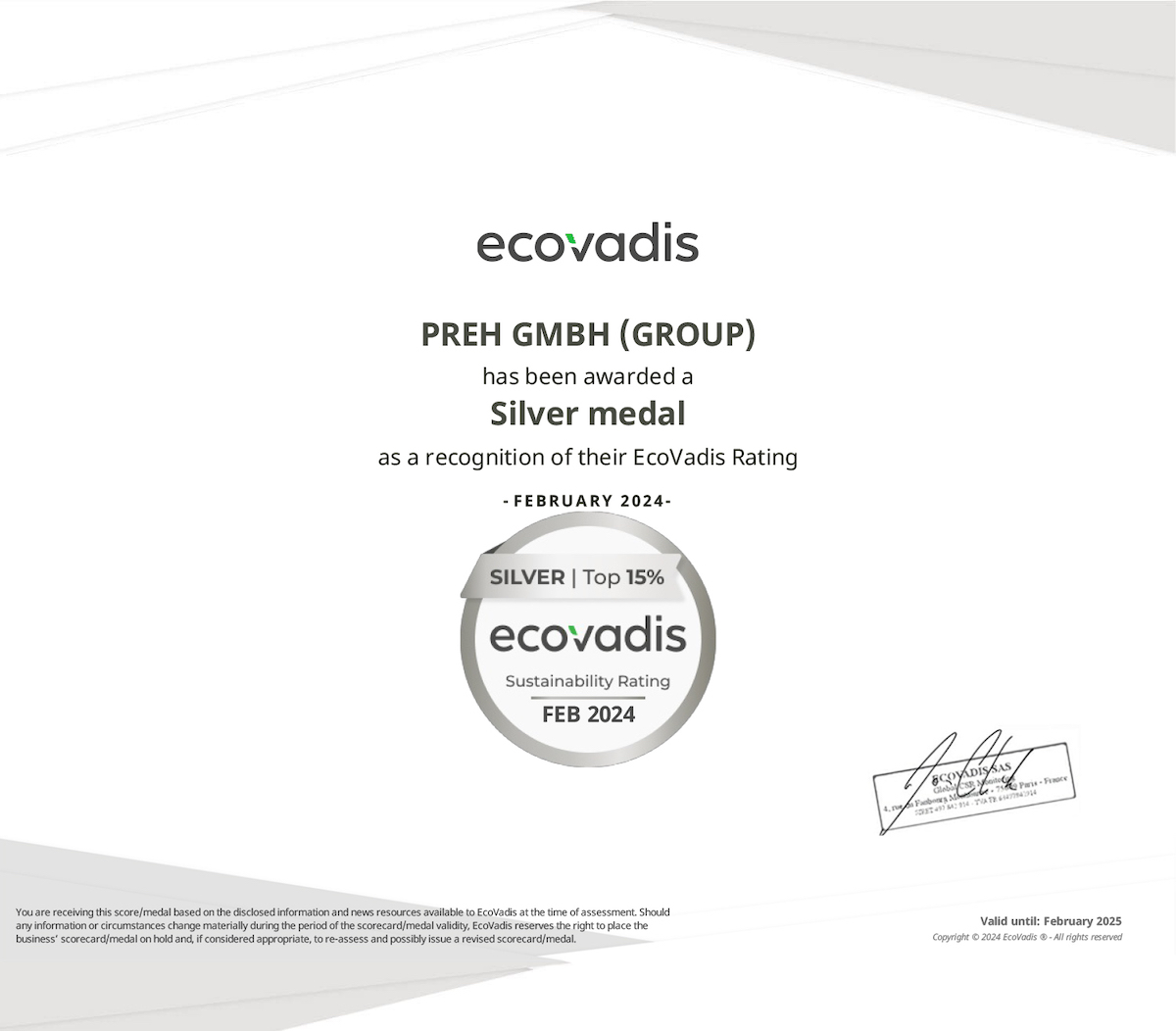

The Preh Group decided to join the EcoVadis platform in 2021 for the assessment of the development of our performance in the fields environment, social and governance (ESG) in a global accepted benchmark.

The Top Management understands the health and safety of all employees as well as the protection of environment

and climate as important corporate guiding principles. We aim to a continuous improvement of our EHS performance

by setting our own EHS targets and implementing appropriate measures.

In order to avoid environmental pollution and conserve natural resources, our current and future activities are regularly

evaluated from an ecological point of view. Legal environmental protection and safety regulations are our minimum standard.

The energy flows are regularly analyzed and evaluated by the energy teams at the respective location and new potentials for

improvement are defined. Before the use of new materials or technical equipment and when designing the work environment,

health and safety risks are identified, evaluated and, as far as possible, eliminated in order to avoid possible hazards.

Health and safety concepts apply to every employee.

The United Nations has found that the trade of certain rare earth minerals is helping to finance the civil conflict in the

Democratic Republic of the Congo (DRC) and certain adjoining countries (covered countries), characterized by violation

of human rights and destruction of environment. These minerals are commonly referred to as “3TG” (tin, tantalum,

tungsten, & gold) and their derivatives.

Preh is committed to the Conflict Minerals reporting requirements of our customers prior to the deadlines. Preh is working

with suppliers to perform the necessary due diligence in determining the potential for Conflict Minerals in our supply chain.

It is our responsibility to avoid risks regarding safety, health and environment during usage of our products. Therefore, legal and regulatory requirements are considered as the minimum standard for our products. Furthermore, the understanding of the requirements of our customers is a further essential component during product development process for fulfillment of these obligations. Our ambitious standards for quality assurance and manufacturing are implemented globally by our employees from development up to the delivery of the serial product. We ensure the compliance with the requirements regarding safety, functionality, appearance and material conformity of our products by internal processes and extensive tests. Our standard gets confirmed externally by regular awards of our customers and by successful certification of our management system regarding quality, environment and occupational safety as well as information security.